Case Study

How Wen-Parker Partnered With a Major Clothing Brand to Deliver Large Quantities of PPE Across the U.S. During the COVID-19 Pandemic

The Challenge:

A Global Supply Chain in Crisis

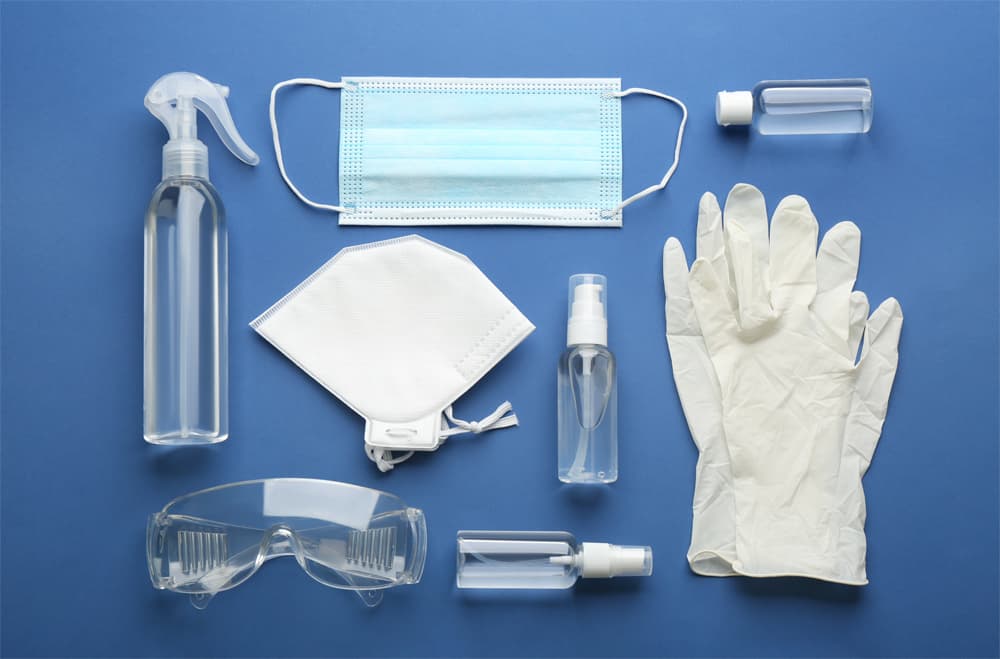

In March 2020, as the COVID-19 pandemic rapidly spread across the globe, a major clothing brand was tasked with a critical mission by the U.S. government: deliver massive quantities of personal protective equipment (PPE) to hospitals across the country.

The majority of the PPE was being produced in Vietnam, with additional supplies sourced from Thailand, Cambodia, China, and Indonesia. However, the challenge was monumental—global supply chains were in turmoil, air freight and ocean freight capacity was severely constrained, and every country in the world was scrambling to secure PPE.

By April 2020, the apparel company had estimated that they would need to move 1,900 CBMs of PPE per week by July. With supply chains at a breaking point, the organization turned to Wen-Parker Logistics, a trusted global freight forwarder known for its ability to manage crisis logistics and provide customized logistics solutions.

The Wen-Parker Solution: Leveraging a Global Network for Speed & Efficiency

When Wen-Parker was tasked with this objective, their team quickly assessed the situation and devised a multi-modal logistics strategy that ensured PPE reached hospitals across the U.S. without delay. They did this through three key steps.

Hong Kong Consolidation

As mentioned earlier, most of the PPE was coming from Vietnam, but a good amount was also being sourced from Thailand, Cambodia, China, and Indonesia. To maximize the amount transferred per shipment, Wen-Parker needed a centralized hub that could consolidate shipping materials. To do this, Wen-Parker worked with regional air and ocean carriers to transport PPE to Hong Kong for consolidation. By streamlining shipments at this central hub, Wen-Parker maximized efficiency before moving goods across the Pacific.

Securing Air Charters & Passenger Airlines

Understanding that speed was essential, Wen-Parker secured dedicated air charters and also leveraged passenger airlines like United Airlines—which had idle aircraft and crew due to reduced travel demand. This innovative approach not only helped the company meet its tight delivery timelines but also provided a much-needed revenue source for airlines during the crisis.

Scaling Up for Unprecedented Demand

As the demand for PPE surged, Wen-Parker adapted quickly. At the project’s peak, Wen-Parker successfully moved 9,600 CBMs of PPE per week—far exceeding the initial estimate of 1,900 CBMs per week. This achievement helped the apparel brand fulfill its contract with FEMA and ensured frontline healthcare workers had the protective gear they needed.

The Results: A Scalable, Reliable PPE Supply Chain

Wen-Parker’s success with the apparel brand didn’t end in the summer of 2020. The company’s ability to navigate supply chain disruptions, leverage alternative shipping routes, and integrate air and ocean solutions allowed it to continue supporting organizations throughout the pandemic. Additionally, Wen-Parker’s proactive planning, global team of industry experts, and strong partnerships made the company a trusted logistics provider when it mattered most.

Need a Logistics Partner for Your Critical Shipments?

When supply chain challenges arise, Wen-Parker Logistics delivers solutions that move your business forward. If you’re looking for a logistics partner that can adapt to crises, optimize global shipping routes, and ensure reliable deliveries, contact Wen-Parker today.

Let’s Navigate Your Supply Chain Challenges Together

Looking for expert logistics solutions tailored to your business? Contact Wen-Parker Logistics today and discover how we can optimize your supply chain for success.